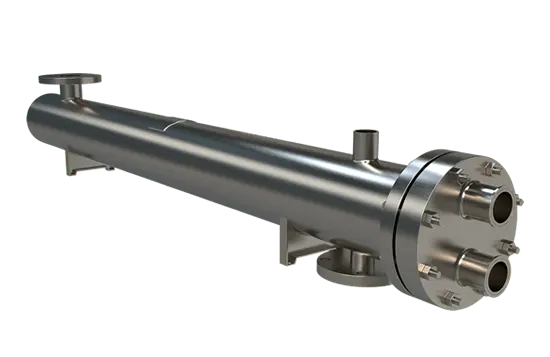

Stainless Steel Shell & Tube Design

Stainless steel shell and tube heat exchangers are engineered for superior heat transfer efficiency while meeting the strictest hygiene standards required in industries such as food and beverage, pharmaceuticals, biotechnology, and cosmetics. These designs prioritize contamination prevention, ensuring product integrity and compliance with regulatory standards. The robust construction of stainless steel ensures durability, corrosion resistance, and compatibility with aggressive cleaning protocols.

The design features a series of stainless steel tubes housed within a cylindrical shell, facilitating efficient heat transfer between two fluids without mixing. One fluid flows through the tubes, while the other circulates around them within the shell. Smooth, crevice-free surfaces minimize bacterial growth, and features like full drainability and clean-in-place (CIP) compatibility simplify maintenance. Custom designs are tailored to specific applications, accounting for factors such as fluid viscosity, flow rates, and temperature requirements, ensuring optimal performance for processes like pasteurization, sterilization, and product cooling.

Design Specifications

Length:

12" to 400"

Diameter:

3" to 48"

Code:

ASME / TEMA

Standard Design Features

- Product Contact Surfaces Polished to 32 RA Finish

- Exterior Polished to a 40 RA Finish

- Fully Drainable and CIP-Compatible Design

- Channel Head Milled from a Single Stainless Steel Block

- ASME-Approved Sanitary Ferrules

- Orbital TIG Welded Tubes to Tubesheet

- ASME Code "U" Stamp and National Board Registration

- Hydrostatic Pressure Testing

- Dye Penetrant Testing

- Passivation for Enhanced Corrosion Resistance

Stainless Steel Shell and Tube Heat Exchanger Design

Our stainless steel shell and tube heat exchangers are meticulously designed to meet the rigorous demands of industries requiring high hygiene and performance standards, such as food, beverage, dairy, and pharmaceuticals.

Types of Shell and Tube Heat Exchanger Designs

Available in both standard and custom configurations, our designs feature 304L or 316L stainless steel for superior corrosion resistance and sanitary compliance. Built to TEMA Class C and ASME standards, they are hydro-tested and code-stamped for reliability. U-tube designs accommodate thermal expansion, while shell expansion bellows support high-temperature swings. Replaceable O-rings and tube bundles, sizes from 4" x 36" to 10" x 54", and 3-A Sanitary Standard upgrades ensure versatility and compliance.

Design Features

Standard designs include 304L stainless steel tubing, welded and bright annealed, with a 40Ra exterior finish. Custom options include 316L stainless steel, seamless 3-A compliant tubes polished to 32Ra, chloride-free insulation jackets, and configurations for vertical or horizontal mounting. Additional features like double tube sheets, expansion joints, and CIP spray ball assemblies enhance functionality and cleanability.

Design Requirements

Our designs incorporate seal-welded tube-to-tubesheet joints, sanitary tri-clamp fittings, polished surfaces, and compliance with 3-A Sanitary Standards and ASME BPE. Gasket materials like PTFE or Viton ensure compatibility with sanitary processes, while CIP compatibility simplifies maintenance.

Applications

These heat exchangers are critical for processes like pasteurization, sterilization, beverage cooling, and pharmaceutical manufacturing. They handle diverse fluids, from low-viscosity juices to high-viscosity dairy products, ensuring safety and regulatory compliance across food, beverage, and pharmaceutical industries.

Benefits of Our Designs

Customizable and durable, our designs offer high pressure and temperature capabilities, energy efficiency, and low maintenance costs. They support aseptic processes, handle particulate fluids, and are easy to inspect and customize, ensuring long-term reliability.

TEMA Standards

Adhering to TEMA Classes B, C, and R, our designs guarantee consistent performance and compliance with industry standards.

3-A Sanitary Standard

Certified to meet 3-A Sanitary Standards, our designs ensure compliance for food and dairy applications, passing sanitary inspections with ease.

Clean-in-Place Design

Our CIP-compatible designs streamline cleaning processes, with thermal modeling ensuring optimal performance for both stock and custom solutions.

Design Upgrades

Enhance your heat exchanger with options like stainless steel cladding, multi-pass configurations, electropolished surfaces, or material upgrades (Duplex, Hastelloy, AL6XN) for specialized applications.

Common FAQs

Stainless Steel Heat Exchanger Applications

SANITARY SYSTEMS

Clean-in-Place (CIP)

Stainless steel heat exchangers designed for CIP processes ensure hygiene and efficiency in sanitary applications.

+ Learn More

FOOD & BEVERAGE • ALCOHOL

Alcohol Production

Our stainless steel heat exchangers support efficient heat transfer for beer, wine, and distilled spirits production.

+ Learn More

FOOD & BEVERAGE • DAIRY

Dairy Processing

From pasteurization to cooling viscous fluids like yogurt, our stainless steel heat exchangers ensure sanitary performance.

+ Learn More