Sanitary Heat Exchangers

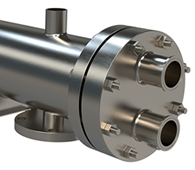

Sanitary Shell and Tube Heat Exchangers

Sanitary applications in industries like food and beverage, pharmaceutical, and dairy processing require uncompromising hygiene and precise temperature control to ensure product safety and quality. Southwest Thermal’s sanitary-grade stainless steel shell and tube heat exchangers are designed to meet these demands, offering exceptional corrosion resistance and compliance with 3A, FDA, and cGMP standards. These units provide efficient heat transfer for processes such as pasteurization, sterilization, fluid heating/cooling, and clean-in-place (CIP) systems, ensuring reliability and hygiene.

Constructed from 316L stainless steel with polished surfaces (Ra = 32 µin), these exchangers prevent microbial growth and facilitate rigorous cleaning protocols. They are customized to handle various process fluids, including viscous liquids and biologics, providing reliable thermal management for sensitive applications. The robust construction ensures durability under continuous operation and repeated cleaning cycles, with ASME and 3A certification available for industry compliance.

The versatility of shell and tube heat exchangers allows for tailored configurations to meet specific sanitary process requirements, making them essential for achieving high-quality results in hygienic environments.

Sanitary heat exchanger operations involve several critical steps to ensure hygiene and efficiency:

- Process Fluid Handling: Process fluids, such as milk, juices, or pharmaceutical intermediates, flow through the stainless steel tubes, with a heating or cooling medium flowing through the shell for efficient heat transfer.

- Temperature Control: Precise regulation of temperatures prevents degradation of sensitive products and ensures consistent quality.

- CIP/SIP Integration: Automated Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems circulate cleaning agents or steam to maintain hygiene and prevent contamination.

- Surface Finish Validation: Polished surfaces (Ra = 32 µin) are verified to meet 3A and FDA standards for cleanliness and microbial control.

- Testing: Post-process testing ensures product purity, temperature, and compliance with sanitary and regulatory standards.

Each stage relies on the precision and durability of stainless steel shell and tube heat exchangers to maintain hygiene, optimize heat transfer, and ensure regulatory compliance.

Sanitary Shell & Tube:

Sanitary Applications

- Food & Beverage Processing

- Pharmaceutical & Dairy

- 3A and FDA Compliant