Certifications for Stainless Steel Heat Exchangers

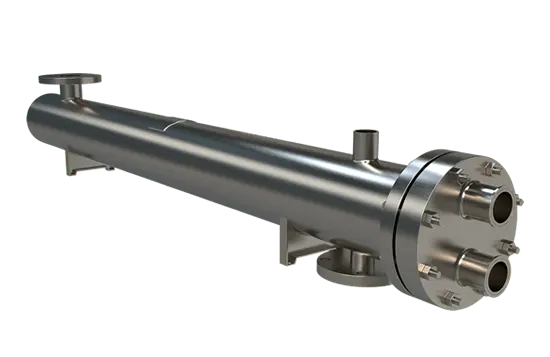

Our stainless steel heat exchangers, including shell and tube, plate and frame, tube-in-tube, and embossed plate designs, are built to comply with rigorous industry certifications. These certifications ensure our products meet the highest standards for quality, safety, and performance in industries such as food and beverage, pharmaceuticals, biotechnology, and chemical processing. Constructed from 304L or 316L stainless steel, our heat exchangers are designed for durability, corrosion resistance, and compliance with stringent regulatory requirements, ensuring reliability in critical applications like pasteurization, sterilization, and cooling.

Certification Standards

ASME:

Section VIII, Division 1

TEMA:

Classes B, C, R

3-A:

Sanitary Standards

Standard Certifications

- ASME Code "U" Stamp

- National Board Registration

- 3-A Sanitary Standard Compliance

- TEMA Class C Certification

- ASME BPE Compliance

- Hydrostatic Pressure Testing

- Dye Penetrant Testing Certification

- Passivation Certification

- ISO 9001 Quality Management

Certified Stainless Steel Heat Exchangers

Our stainless steel heat exchangers are designed and manufactured to meet stringent industry certifications, ensuring compliance with safety, quality, and performance standards for industrial and sanitary applications.

Key Certifications

Our heat exchangers, including shell and tube, plate and frame, tube-in-tube, and embossed plate designs, are certified to meet ASME Section VIII, Division 1, TEMA Classes B, C, and R, and 3-A Sanitary Standards. These certifications guarantee reliability, safety, and hygiene. Additional certifications include ISO 9001 for quality management, National Board Registration, and ASME BPE for bioprocessing equipment, ensuring compliance across industries.

Certification Features

Our certified heat exchangers feature 304L or 316L stainless steel construction, polished to 32Ra for product contact surfaces and 40Ra for exteriors. They include ASME-approved ferrules, orbital TIG-welded joints, and full drainability. Certifications like hydrostatic pressure testing, dye penetrant testing, and passivation ensure durability and corrosion resistance, while comprehensive documentation supports validation.

Certification Requirements

Our heat exchangers meet rigorous requirements, including seal-welded tube-to-tubesheet joints, sanitary fittings, and compliance with 3-A Sanitary Standards and ASME BPE. Gasket materials like PTFE or Viton ensure compatibility, while certifications like ISO 9001 and National Board Registration validate quality and safety.

Applications

Certified stainless steel heat exchangers are critical for processes like pasteurization, sterilization, chemical processing, and pharmaceutical manufacturing. They ensure compliance with regulatory standards in food, beverage, dairy, and biotech industries, handling diverse fluids while maintaining safety and quality.

Benefits of Certified Designs

Certified heat exchangers offer assured compliance, enhanced durability, and reliability. They support high-pressure and high-temperature applications, reduce maintenance costs, and ensure safety and hygiene, meeting the needs of regulated industries.

TEMA Standards

Our heat exchangers adhere to TEMA Classes B, C, and R, ensuring consistent performance and reliability in industrial applications.

3-A Sanitary Standard

Our 3-A certified designs meet stringent sanitary requirements for food and dairy applications, ensuring compliance and passing inspections without issues.

ASME and ISO Certifications

ASME Code "U" Stamp and ISO 9001 certifications validate our commitment to quality, safety, and performance, ensuring our heat exchangers meet global standards.

Custom Certifications

We offer custom certification options, including material upgrades (Duplex, Hastelloy, AL6XN) and enhanced testing protocols, to meet specific industry requirements.