Clean-in-Place (CIP) Heat Exchangers

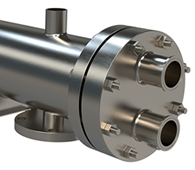

Sanitary Shell and Tube Heat Exchangers

Clean-in-Place (CIP) systems are critical for industries requiring stringent hygiene standards, such as food and beverage processing, pharmaceutical production, and other sanitary applications. Southwest Thermalís sanitary-grade stainless steel shell and tube heat exchangers are designed specifically for CIP compatibility, offering exceptional corrosion resistance and seamless integration with automated cleaning processes. These units ensure efficient heat transfer while allowing thorough cleaning without disassembly, maintaining product quality and hygiene.

Constructed from 316L stainless steel with polished surfaces, these exchangers prevent microbial growth and facilitate easy cleaning with CIP solutions. They are customized to handle various process fluids and cleaning agents, providing reliable thermal management for applications like pasteurization, sterilization, and pharmaceutical processing. The robust construction ensures durability under continuous operation and repeated cleaning cycles, with ASME certification available for industry compliance.

The versatility of shell and tube heat exchangers for CIP applications allows for tailored configurations to meet specific process and sanitation needs, making them essential for maintaining high-quality standards in hygienic environments.

CIP heat exchanger operations involve several critical steps to ensure hygiene and efficiency:

- Process Operation: Process fluids flow through the stainless steel tubes, with a heating or cooling medium flowing through the shell for efficient heat transfer.

- CIP Preparation: The system is flushed to remove residual process fluids before introducing cleaning solutions.

- CIP Cleaning: Automated CIP systems circulate cleaning agents (e.g., caustic, acid, or sanitizers) through the exchanger to remove residues and contaminants.

- Rinsing: Clean water is circulated to remove cleaning agents, ensuring no residue remains.

- Testing: Post-CIP testing verifies cleanliness and compliance with hygiene standards before resuming production.

Each stage relies on the precision and durability of stainless steel shell and tube heat exchangers to maintain hygiene and optimize heat transfer efficiency.

Sanitary Shell & Tube:

CIP Applications

- Efficient Cleaning

- Food & Beverage Processing

- Custom and Standard Units

Industrial Shell & Tube:

CIP Applications

- Budget Friendly

- Multiple Materials Available

- Steam-to-Water Service