Sanitary & Industrial Heat Exchangers

High-Performance Shell & Tube, Tube-in-Tube, Plate & Frame, and More

At Stainless Heat Exchangers, we specialize in precision-engineered stainless steel heat exchangers for sanitary and industrial applications. Our offerings include Shell & Tube, Tube-in-Tube, Plate & Frame, Embossed Plate, and Brazed Plate designs, constructed with 316L stainless steel to ensure corrosion resistance and compliance with 3A and FDA standards. Ideal for Clean-in-Place (CIP), dairy pasteurization, sauces, liquid eggs, wastewater, evaporating, condensing, and tank cooling/heating, we partner with you to deliver cost-effective, high-quality heat transfer solutions.

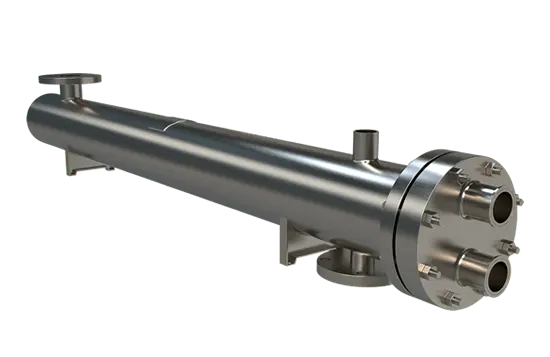

- Shell & Tube: Built for high-pressure durability, these exchangers excel in sanitary applications like dairy pasteurization, pharmaceutical processing, and wastewater treatment, with 3A compliance available.

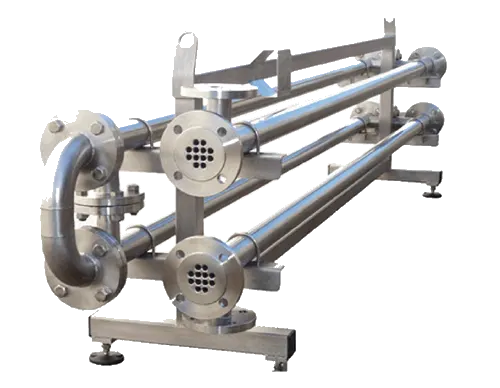

- Tube-in-Tube: Perfect for high-viscosity fluids or solids in suspension, such as sauces and liquid eggs, offering customizable sanitary fittings for precise heat transfer.

- Plate & Frame: High-efficiency units with close approach temperatures, ideal for beverage processing, dairy pasteurization, and wastewater applications, with easy cleaning and reduced fouling.

- Clean-in-Place (CIP): Designed to support CIP protocols, ensuring hygienic conditions for food, beverage, and pharmaceutical production, maintaining product integrity.

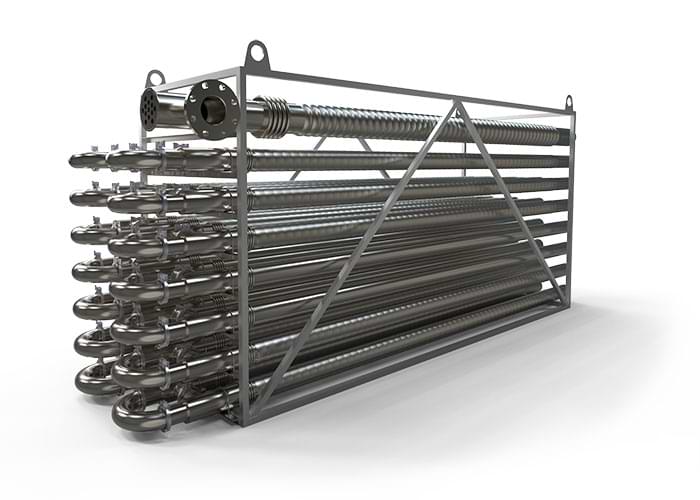

- Evaporators & Condensers: Efficiently handle phase changes for food processing, pharmaceutical concentration, and solvent recovery, meeting sanitary standards.

- Brazed & Embossed Plate: Compact solutions for refrigeration, hydronics, CO2 systems, tank cooling/heating, and drip elimination in sanitary and industrial settings.

Shell & Tube:

High durability for sanitary and industrial applications

- Steam to Water

- Condensing

- Heating & Cooling

Tube-in-Tube:

Ideal for high-viscosity fluids and solids in suspension

- Sauces & Pulp

- High Viscosity Fluids

- Solids in Suspension

Plate & Frame:

High-efficiency heat transfer for sanitary processes

- Food & Beverage

- Brewing & Distilling

- Cooling Tower Isolation

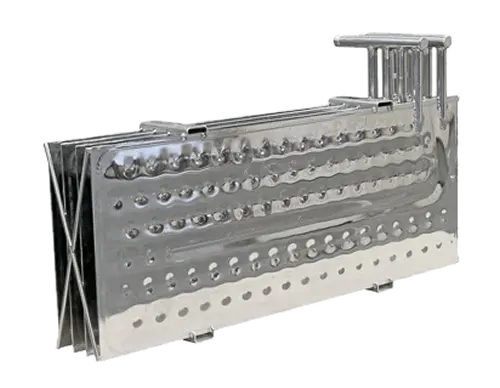

Embossed Plate:

Compact solutions for tank and line integration

- Tank Cooling/Heating

- Food Production Lines

- Drip Elimination

Brazed Plate:

High-efficiency for compact applications

- Evaporators

- Condensors

- Fluid-to-Fluid

Custom & Sanitary Heat Transfer Solutions

Since our inception we have provided top-tier heat transfer solutions, specializing in stainless heat exchangers and applications for industries like food, beverage, dairy, and pharmaceuticals. Our expert engineers assist in selecting the optimal heat exchanger, Shell and Tube, Tube-in-Tube, Plate and Frame, Embossed Plate, or Brazed Plate for applications including CIP, dairy pasteurization, sauces, liquid eggs, wastewater, evaporating, condensing, and tank cooling/heating.

Shell and Tube exchangers offer robust, high-pressure performance for dairy, pharmaceutical, and wastewater applications. Tube-in-Tube designs excel with high-viscosity fluids like sauces and liquid eggs. Plate and Frame units provide unmatched efficiency for beverage and dairy processing with easy maintenance. Embossed Plate exchangers are ideal for tank cooling/heating and food production lines, while Brazed Plate units suit refrigeration, hydronics, and CO2 systems. Constructed from 316L stainless steel, our exchangers ensure corrosion resistance and compliance with 3A and FDA standards.

We offer pre-engineered and custom solutions at competitive prices, guiding you from design to production.

Contact our sales team at 1-805-484-2992 (M-F, 8am-5pm) for tailored heat exchanger solutions.